Product information

- Name:

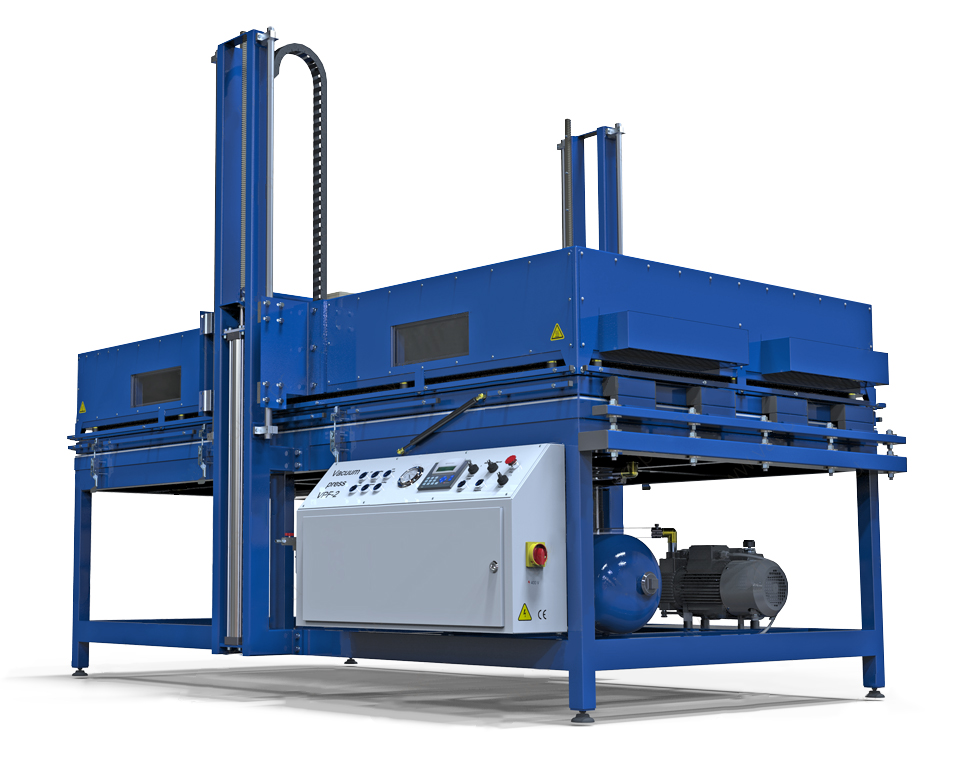

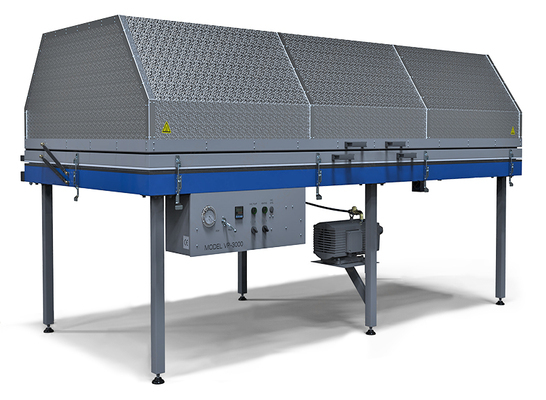

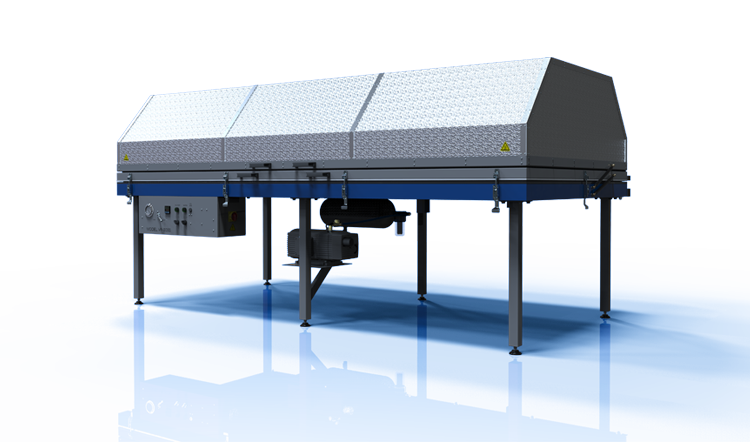

- Model: EC-VMP1325S , EC-VMP1325D

- Working voltage: 380 V

- Working Area: 1300X2500mm

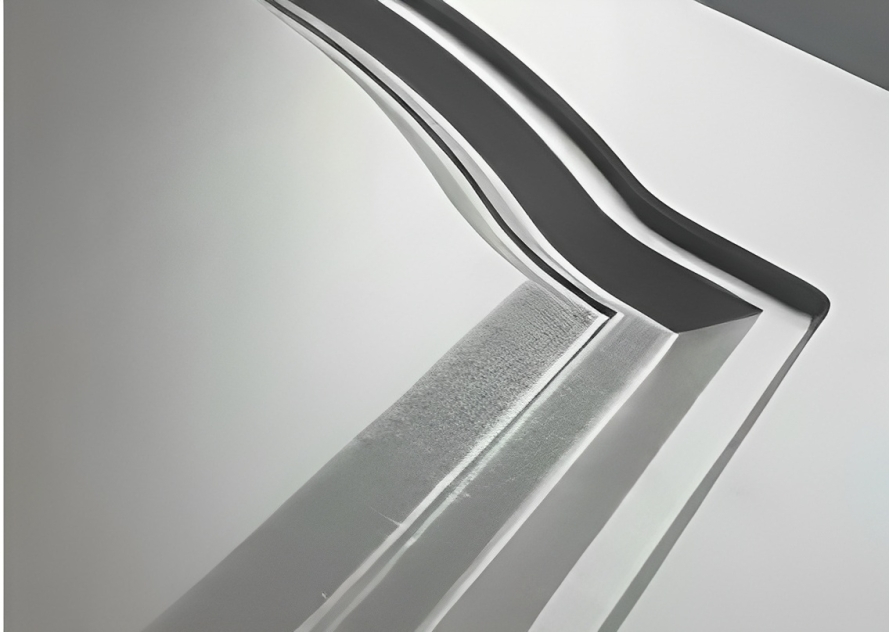

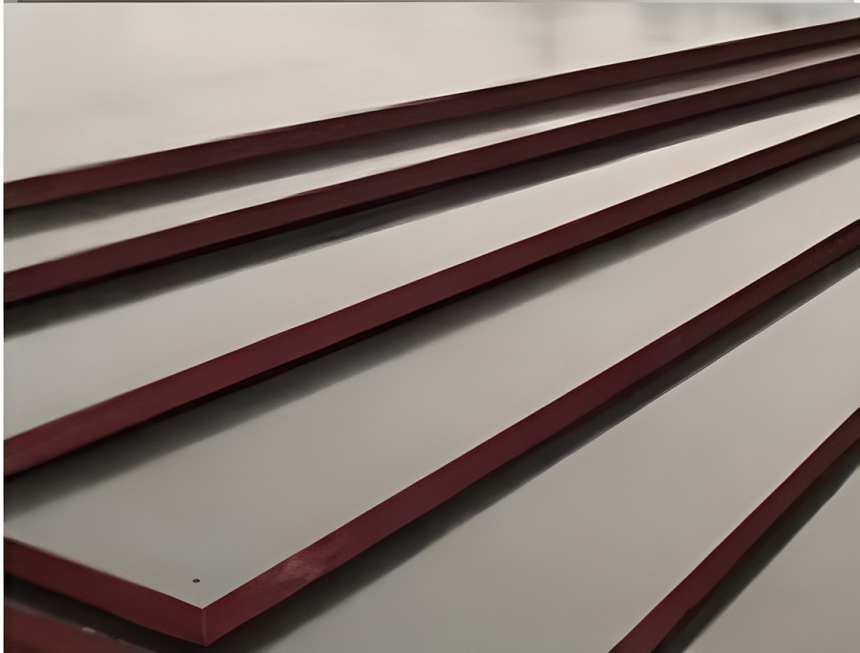

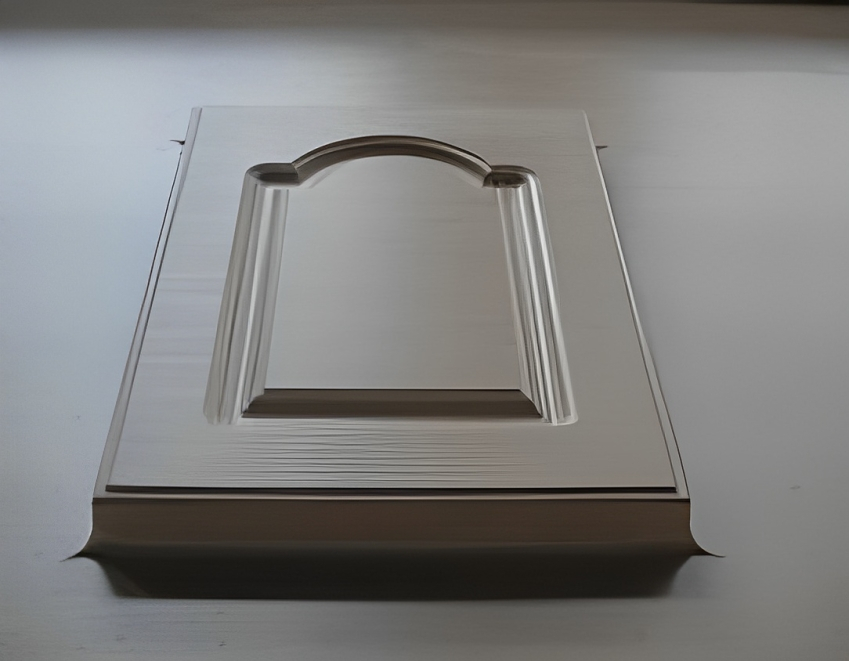

- Application: High-grade PVC , transfer film, leather furniture surface coating, etc.

Machine Features

- The controller's PLC consists of very few wiring elements making it easy to operate and also lowers the chance of failure during operation.

- Easy maintenance and high vacuum efficiency, air flues connecting working table are chrome-plated seamless steel tube, allows for stable running and noiseless operation.

- The working table is connected by bolts, easy dismounting and cleaning. PVC pressing frame adopts 6061T6 aluminum alloy extrusions and it is not hot after a long time of working. Table running adopts chain of transmission and Frequency control, with low fault rate, smoothly running keep work-piece no shifting.

- Thicker heating and thermal insulation structure for main heating oven, it will save electricity 30% than before.

Specifications

| Model | EC-VMP2531 |

| Working Area | 1300X2500mm |

| Maximum processing height | 60mm,include buttom plate |

| Rated pressure | ≥-0.095MPa |

| Total power | 25KW |

| Actual power consumption | 12KW |

| Power supply | 3ph,380V,50HZ |

| Heating system | Iron air dry electric heating tube+Aluminum heat sinks |

| Temperature control system | Microcomputer time proportional control |

| Transmission | Aluminum housing efficient motor + rack & pinion drive |

| Vacuum pump | straight rotary vane vacuum pump |

| Machine weight | 2500kg |

| Adsorption | Large flow filter + pure copper solenoid valve, with multiple adsorption function |

| Heat preservation | Using high quality rock wool | Electrical control | Traditional button control O.E.M |

Machine Details

1. Laser machine brand: EngineersChoices